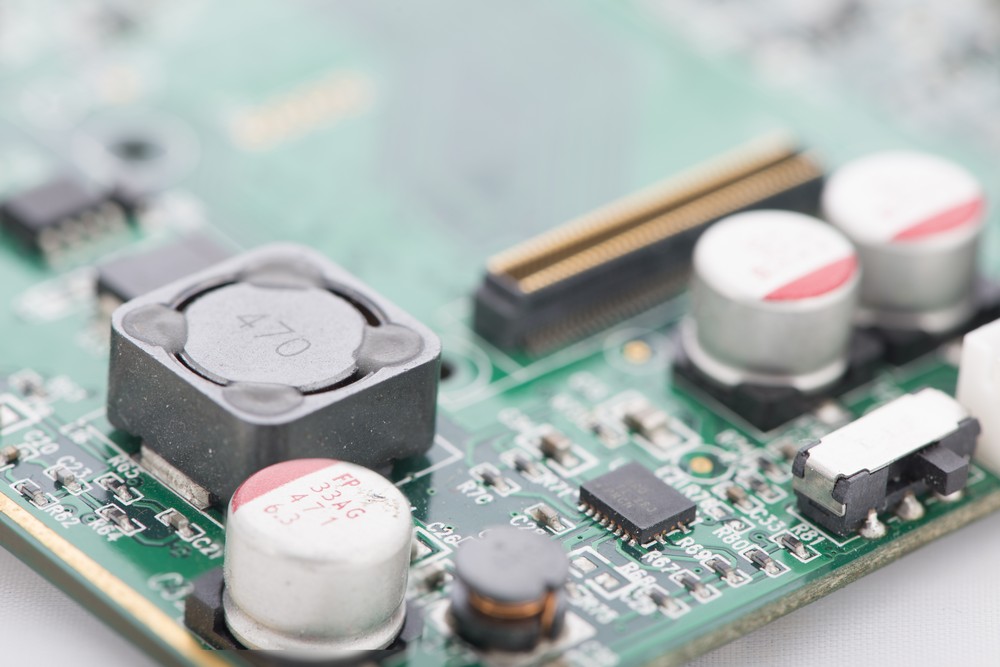

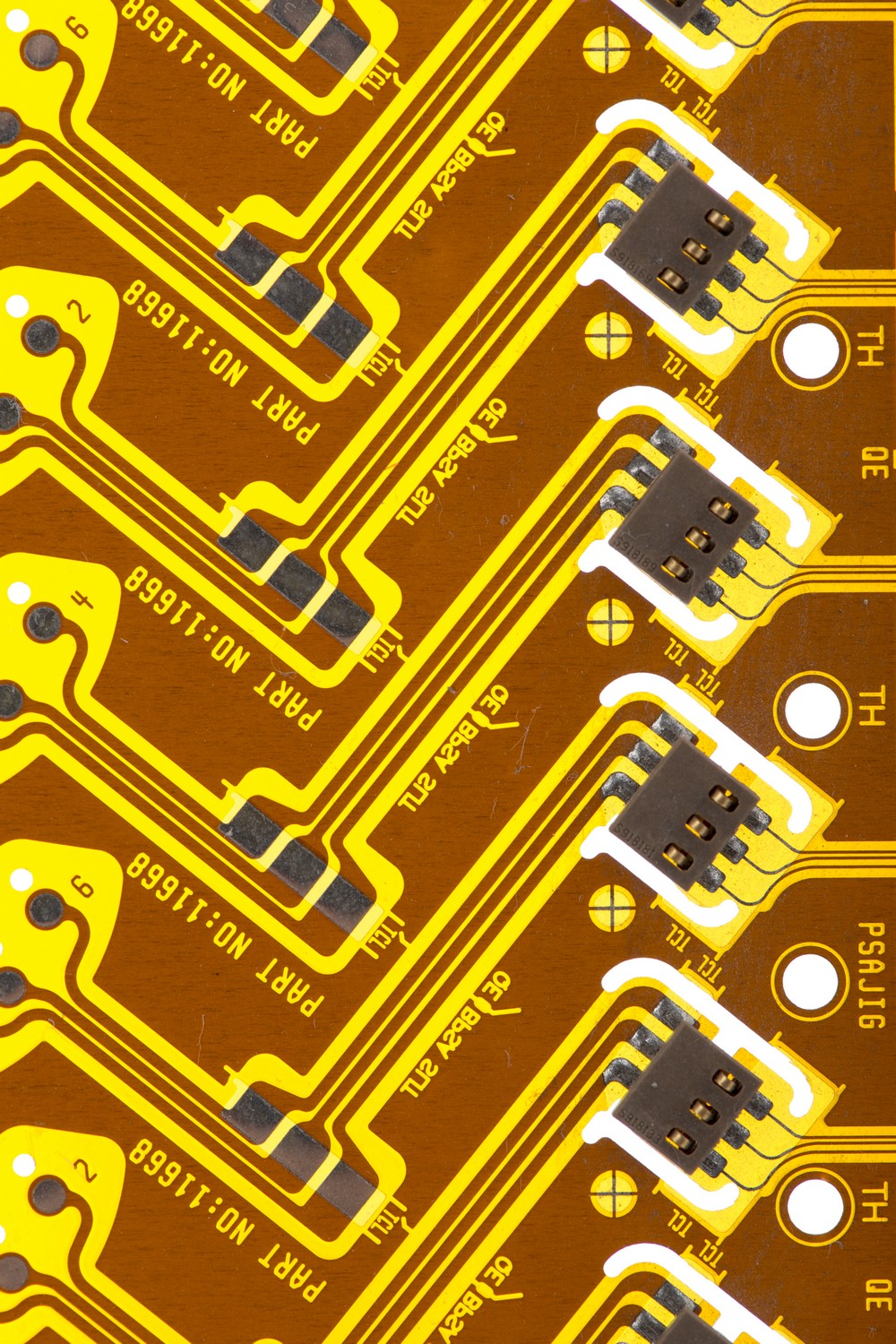

BH provides complete turnkey solutions involving printed circuit board (PCB) assemblies, box builds and wire harness assemblies. We provide quick-turn prototype, production PCB assembly with surface-mount (SMT), through-hole (THT) and mix components. We can handle small quantity as well as volume productions.

Our Technology Capabilities:

SMT & THT

Wire bonding and encapsulation

Chip On Board/Flex (COB)

Electro-Mechanical & Box-Build Assembly

Lead Free/Leaded Process Capabilities

BGA Repair/Rework Capability

PCB layer count up to 24 layers

Ultra sonic cleaning

BH adopts a variety of testing methodologies to ensure the assembled boards are functional prior to shipping. They are:

Basic Quality Test: visual inspection.

X-ray Inspection: tests for BGAs, QFN and bare PCBs.

AOI Checks: tests for solder paste, 0201 components, missing components and polarity.

ICT (In-Circuit Test) / Functional test: according to the customer’s testing procedures.